Revolutionizing Materials Science with Precision and Insight: How Genuine Testing Leads the Future of Surface Analysis, Trace Elemental Analysis, and Metals & Alloys Research

In today’s innovation-driven industries, materials are no longer judged solely by their bulk properties. Performance, safety, sustainability, and compliance now depend on what happens at the surface, at the atomic level, and within complex metal and alloy systems. From aerospace and automotive to energy storage, construction, and healthcare, organizations require deeper, more accurate insights into materials than ever before.

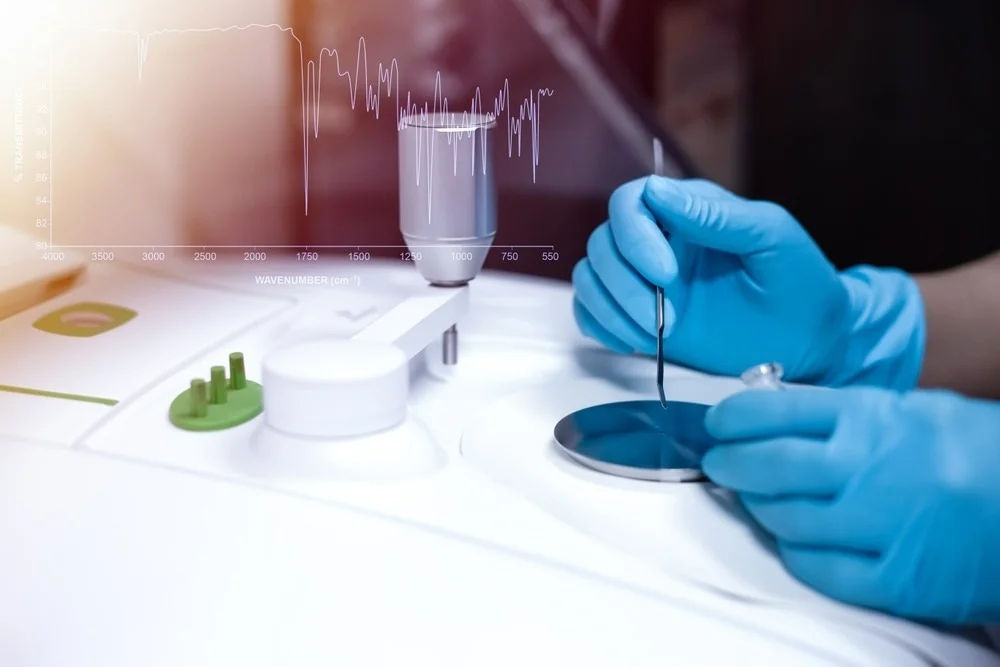

This is where Genuine Testing, a trusted Contract Research Organization (CRO), stands at the forefront. By combining decades of scientific expertise with cutting-edge laboratory technologies, Genuine Testing empowers industries with advanced surface analysis, trace elemental analysis, and comprehensive metals and alloys testing—delivering data-driven confidence from concept to commercialization.

The New Era of Materials Testing: Why Precision Matters More Than Ever

As materials evolve, so do the challenges associated with them. Lightweight alloys, high-performance coatings, advanced composites, and next-generation battery materials demand analytical techniques that can operate at microscopic and even nanoscopic levels. Modern material failures often originate from surface defects, trace impurities, or elemental inconsistencies that traditional testing methods simply cannot detect.

Today’s industries are embracing high-resolution surface characterization, ultra-sensitive elemental detection, and data-rich alloy analysis to ensure reliability, regulatory compliance, and long-term performance. Genuine Testing has aligned its services with these demands, offering scientifically rigorous and industry-relevant solutions that bridge research and real-world application.

Surface Analysis: Unlocking the Story at the Material’s Boundary

Surface analysis has become one of the most critical areas in materials science. Whether it’s a protective coating on a turbine blade, a biomedical implant, or a semiconductor component, the surface often determines how a material interacts with its environment.

Latest Trends in Surface Analysis

Modern surface analysis focuses on:

Nanoscale characterization of coatings and thin films

Failure analysis to identify corrosion, wear, or delamination

Surface contamination detection impacting adhesion or performance

Interface studies between layered materials

Advanced microscopy and analytical techniques now allow scientists to visualize and quantify surface features with extraordinary clarity.

Genuine Testing’s Approach to Surface Analysis

At Genuine Testing, Surface analysis is powered by high-resolution microscopy and advanced analytical instrumentation. These technologies enable detailed imaging, compositional mapping, and defect identification at micro and nano scales. By understanding surface chemistry and morphology, clients gain actionable insights to:

Improve coating durability

Enhance product lifespan

Optimize manufacturing processes

Prevent costly material failures

Every analysis is conducted with precision, transparency, and adherence to international quality standards—ensuring results you can trust.

Trace Elemental Analysis: Seeing What Others Miss

Even the smallest impurity can dramatically affect a material’s performance. Trace elements may influence corrosion resistance, electrical conductivity, mechanical strength, or regulatory compliance. As materials become more sophisticated, Trace elemental analysis has shifted from optional to essential.

Emerging Technologies in Trace Elemental Detection

The latest advancements in elemental analysis emphasize:

Ultra-low detection limits for critical impurities

Multi-element analysis in complex matrices

Rapid, high-throughput testing for industrial scalability

Environmental and regulatory compliance testing

These trends are particularly vital for industries such as aerospace, energy, electronics, and healthcare, where trace contaminants can lead to catastrophic failures or regulatory setbacks.

How Genuine Testing Delivers Confidence Through Elemental Analysis

Genuine Testing leverages state-of-the-art chemical and elemental analysis techniques to identify and quantify trace elements with exceptional accuracy. Their expert scientists translate complex elemental data into clear, actionable insights that help clients:

Ensure material purity and consistency

Meet strict regulatory and quality requirements

Identify contamination sources

Enhance product reliability and safety

With a strong emphasis on confidentiality and compliance, Genuine Testing ensures that sensitive data remains secure while delivering results that accelerate innovation.

Metals and Alloys: Engineering Performance from the Inside Out

Metals and alloys remain the backbone of modern industry, but their complexity continues to grow. Advanced alloys are now engineered for extreme environments—high temperatures, corrosive conditions, and mechanical stress—making detailed analysis more critical than ever.

Key Trends in Metals and Alloys Research

The latest developments in Metals and alloys testing include:

Microstructural analysis to optimize strength and durability

Phase identification for advanced alloy systems

Failure and fracture analysis to prevent repeat issues

Lightweight and high-performance alloy development

These trends support industries striving for efficiency, sustainability, and enhanced performance.

Genuine Testing’s Expertise in Metals and Alloys Analysis

As a leading CRO, Genuine Testing provides comprehensive testing services for metals and alloys, from raw material evaluation to failure analysis. Their advanced laboratory capabilities allow for:

Detailed microstructural examination

Precise elemental composition analysis

Corrosion and performance assessment

Research-driven optimization of alloy formulations

By integrating surface analysis and trace elemental data with metals and alloys research, Genuine Testing delivers a holistic understanding of material behavior—empowering clients to make informed, confident decisions.

Technology Meets Collaboration: The Genuine Testing Difference

What truly sets Genuine Testing apart is not just advanced instrumentation, but a client-focused, collaborative approach. Every project begins with understanding the client’s goals, regulatory requirements, and technical challenges.

A Transparent, End-to-End Process

From sample submission to final reporting, Genuine Testing follows a structured and transparent workflow:

Consultation & Planning – Aligning testing strategies with client objectives

Custom Methodology Design – Selecting the right analytical tools and protocols

Laboratory Execution – Conducting tests with strict quality controls

Data Analysis & Interpretation – Transforming data into meaningful insights

This process ensures efficiency, accuracy, and results that directly support innovation and commercialization.

Supporting Innovation Across Industries

Genuine Testing’s material testing and research services support a wide range of industries, including:

Aerospace and automotive

Construction and infrastructure

Energy and battery materials

Healthcare and medical devices

Environmental and sustainability-focused research

By staying ahead of technological trends and continuously refining methodologies, Genuine Testing remains a trusted partner for organizations seeking reliability, compliance, and scientific excellence.

Looking Ahead: The Future of Materials Testing with Genuine Testing

As materials science continues to evolve, the demand for advanced surface analysis, ultra-sensitive trace elemental analysis, and comprehensive metals and alloys research will only grow. Digital integration, automation, and data-driven decision-making are shaping the future of laboratory testing—and Genuine Testing is already aligned with this trajectory.

By combining precision, innovation, and integrity, Genuine Testing continues to empower industries with insights that matter. Their commitment to excellence, confidentiality, and collaboration ensures that every project not only meets today’s standards but anticipates tomorrow’s challenges.

Conclusion: Precision You Can Trust, Innovation You Can Build On

In an era where materials define success, choosing the right testing and research partner is critical. Genuine Testing stands as a leader in surface analysis, trace elemental analysis, and metals and alloys research—delivering cutting-edge solutions backed by scientific rigor and real-world relevance.

For organizations seeking accuracy, compliance, and innovation under one roof, Genuine Testing is more than a laboratory—it’s a strategic partner in progress.