Adhesives and Rubbers

At Genuine Testing, we offer specialized adhesives and rubbers testing services to help manufacturers and engineers assess material integrity, optimize performance, and solve failures. Whether you’re developing new elastomeric products, qualifying adhesive systems, or investigating product failures, our advanced analytical capabilities ensure you get reliable, actionable results.

Our Adhesives & Rubbers Testing Capabilities

We analyze a wide variety of rubber materials and adhesive formulations to help you achieve optimal performance and meet requirements. Our services include:

Material Identification & Composition

Determine the type of rubber or adhesive, identify fillers, plasticizers, and other additives.Mechanical & Physical Property Testing

Evaluate elasticity, tensile strength, hardness, abrasion resistance, and elongation.Thermal & Environmental Testing

Assess thermal stability, aging behavior, UV resistance, and chemical compatibility.Failure Analysis

Investigate causes of cracking, delamination, loss of adhesion, or degradation.

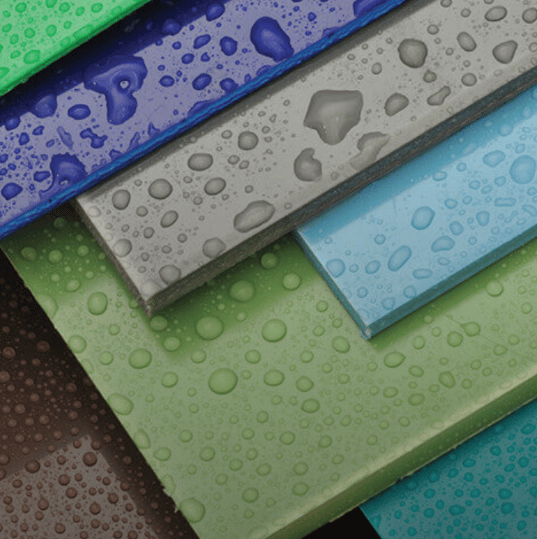

Materials We Test

Our laboratory routinely works with a variety of adhesives and elastomeric materials, including:

Natural rubber

Nitrile (NBR), EPDM, and silicone rubbers

Polyurethane (PU) elastomers

Acrylic and epoxy adhesives

Hot-melt and pressure-sensitive adhesives

Urethane and cyanoacrylate systems

Industries We Serve

Our adhesives and rubbers testing supports applications in:

Automotive & Transportation

Aerospace & Defense

Medical Devices & Healthcare

Electronics & Electrical

Construction & Infrastructure

Consumer Goods & Packaging