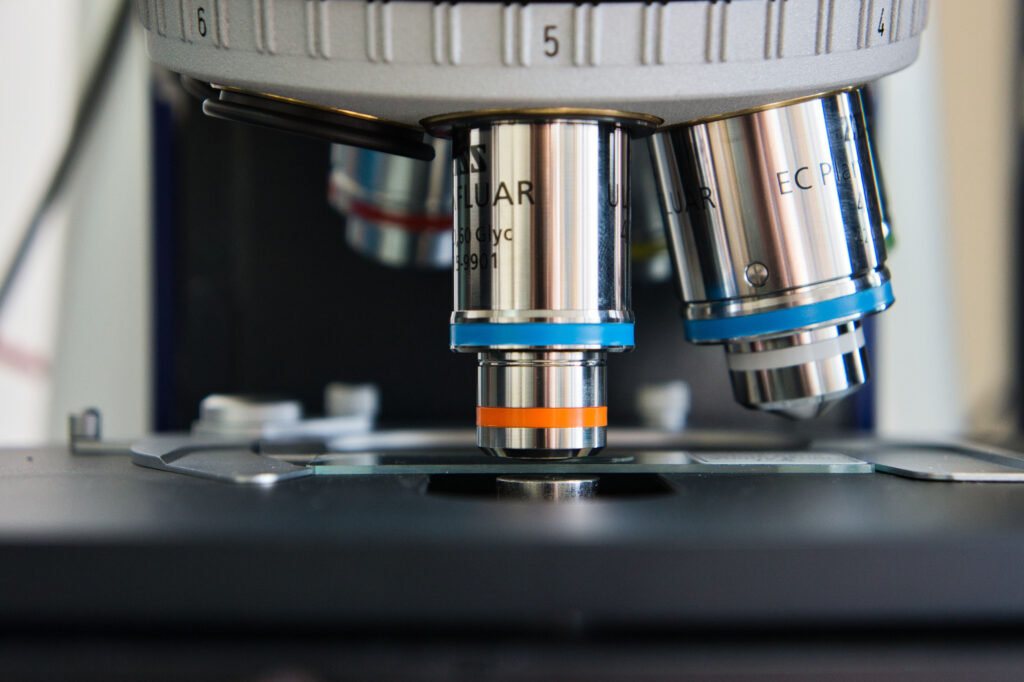

Advanced Microscopy

At Genuine Testing, our advanced microscopy analysis services provide unparalleled insight into the microstructure and composition of materials. Using state-of-the-art tools like Scanning Electron Microscopy (SEM), Transmission Electron Microscopy (TEM), and Dual Beam FIB/SEM, we help you uncover critical details that drive research, development, and failure analysis. Our advanced microscopy testing solutions enable you to visualize surfaces, cross-sections, and internal structures at nanoscale resolution. These methods are essential for identifying defects, analyzing coatings and films, measuring particle size, and investigating material morphology with precision.

Why Choose Genuine Testing for Advanced Microscopy?

Comprehensive sample preparation and analysis of a wide variety of materials

Expertise in failure analysis and root cause identification

Diverse instrumentation to tackle complex challenges

Fast turnaround times and clear, actionable results

Person-to-person communication with expert staff throughout the process

Whether you’re working on process development, quality control, or troubleshooting product failures, our team is ready to support your goals with reliable data and insight.

Our Advanced Microscopy Techniques

We offer a wide array of techniques to meet your specific needs, including:

Scanning Electron Microscopy (SEM):

High-resolution imaging of surface and near-surface features with excellent depth of field. Coupled with EDS, SEM also provides elemental composition analysis.Transmission Electron Microscopy (TEM):

Ultra-high-resolution imaging of thin samples to investigate internal structures, crystallography, and elemental distribution at the atomic level.Scanning Transmission Electron Microscopy (STEM):

Combines TEM and SEM advantages for advanced failure analysis and elemental mapping.Dual Beam FIB/SEM:

Precise sample preparation and imaging, enabling “cut and look” studies of difficult-to-access features and sub-surface layers.Elemental Analysis:

Using techniques such as EDS (Energy Dispersive Spectroscopy) and EELS (Electron Energy Loss Spectroscopy) to map elemental composition and detect impurities.

Applications of Advanced Microscopy

Our advanced microscopy testing is applied to a wide range of industries and materials, including:

Nanoparticles, alloys, and metals

Thin films and coatings

Ceramics and composites

Integrated circuits and semiconductor devices

Polymers and glass substrates

We help identify:

Metal migration and voids

Cracks, delaminations, and thickness uniformity issues

Particle contamination and defect origins

Microstructural integrity of complex materials

Industries We Serve

Some of the key industries we work with include:

Electronics & Semiconductors

We help manufacturers of integrated circuits, microchips, and other semiconductor components analyze thin films, identify defects, and validate manufacturing processes with nanometer-scale accuracy.Automotive & Aerospace

Our advanced microscopy testing ensures the reliability and performance of critical materials, coatings, and assemblies in safety-critical environments, helping meet stringent industry standards.Medical Devices & Healthcare

We assist medical device developers and manufacturers in analyzing material integrity, surface coatings, and microstructure to meet regulatory requirements and ensure patient safety.Energy & Renewable Technologies

From batteries and fuel cells to solar panels and wind components, our microscopy services are used to study materials and processes that improve efficiency and longevity of energy solutions.