Composite Materials Evaluation Services

Composite materials are increasingly used in high-performance and lightweight applications due to their exceptional strength-to-weight ratio, design flexibility, and tailored performance characteristics. However, the complex, multi-phase nature of composites requires specialized testing and evaluation to fully understand their behavior under real-world conditions. At Genuine Testing, we provide comprehensive composite materials evaluation services to help organizations validate performance, ensure reliability, and meet demanding industry requirements. As a trusted Contract Research Organization (CRO), we support manufacturers, engineers, and R&D teams with advanced testing and scientific expertise for fiber-reinforced polymers, layered composites, and engineered composite systems. Our evaluations help reduce uncertainty, optimize designs, and ensure long-term structural integrity in critical applications.

Understanding Composite Materials

Composite materials consist of two or more distinct constituents typically a reinforcement (such as fibers or particles) embedded in a matrix material to achieve properties that cannot be attained by individual components alone. Common composite systems include carbon fiber composites, glass fiber composites, and hybrid or multi-layer structures.

Key challenges in composite materials include:

Anisotropic mechanical behavior

Interfacial bonding between phases

Layer-to-layer consistency

Damage tolerance and failure progression

Environmental sensitivity

Our Composite Materials Evaluation Capabilities

Genuine Testing offers a broad range of composite materials evaluation services tailored to the specific material system, application, and service environment. Our laboratory combines mechanical testing, materials characterization, and failure analysis to deliver a complete understanding of composite performance.

Our composite evaluation capabilities include:

Mechanical property testing of composite laminates

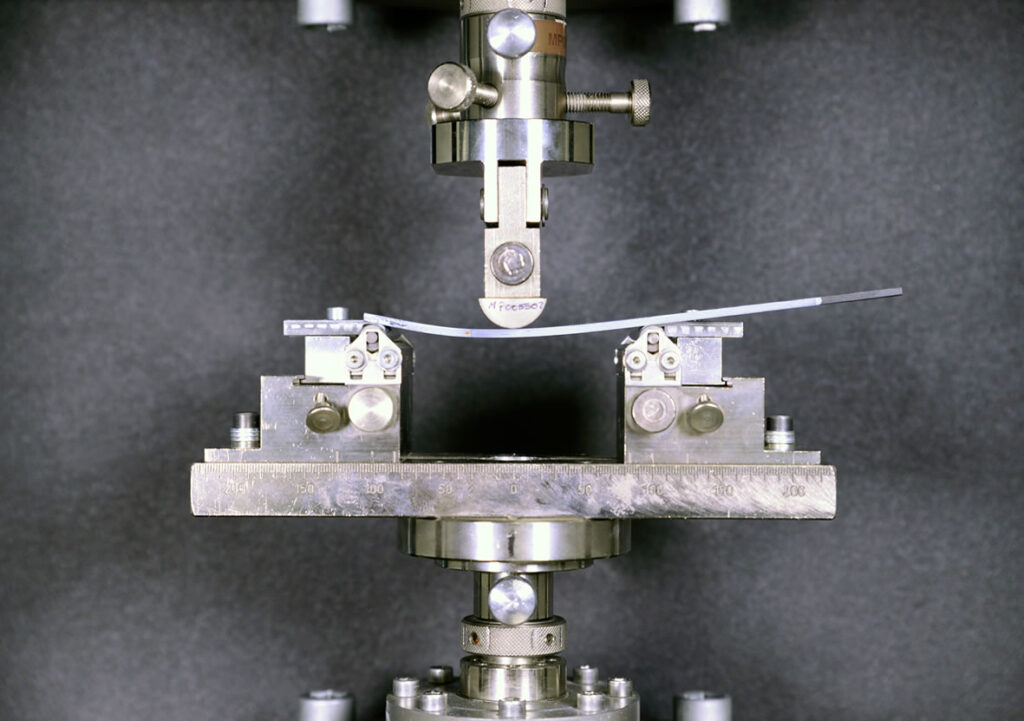

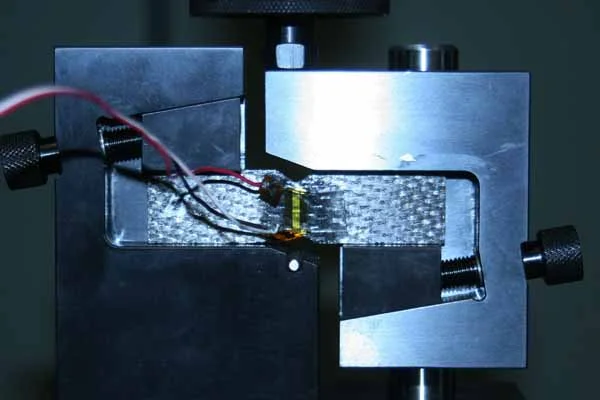

Interlaminar strength and adhesion assessment

Flexural, tensile, and compressive performance evaluation

Damage tolerance and failure behavior analysis

Quality and consistency assessment across batches

Mechanical & Environmental Performance Analysis

Composite materials often operate in demanding environments where mechanical loads are combined with temperature, moisture, or chemical exposure. At Genuine Testing, we evaluate how these factors influence composite behavior over time.

Our performance analysis may include:

Load-dependent deformation and strength evaluation

Assessment of matrix cracking and fiber failure

Evaluation of delamination and interfacial damage

Comparison of composite configurations and layups

Correlation of laboratory results with service conditions

Industries We Support

Composite materials evaluation is essential across industries where lightweight design, high strength, and reliability are critical. We support clients in a wide range of sectors, including:

Aerospace & Defense – structural composites and flight-critical components

Automotive & Transportation – lightweight panels and structural assemblies

Energy & Renewables – wind turbine blades and composite housings

Industrial Manufacturing – engineered composite components

Medical Devices – composite structures requiring strength and consistency

Our evaluations are tailored to industry-specific performance requirements and regulatory expectations.

Why Composite Materials Evaluation Is Critical

Unlike traditional materials, composite failure can be complex and progressive, making it difficult to detect without proper testing. Composite materials evaluation helps organizations:

Validate material performance and design assumptions

Identify manufacturing defects or inconsistencies

Improve safety margins and damage tolerance

Reduce risk of unexpected failures

Support certification and regulatory compliance

Early and thorough evaluation ensures composite materials deliver their intended benefits without compromising safety or reliability.

Why Choose Genuine Testing

Clients choose Genuine Testing for composite materials evaluation because of our deep technical expertise and CRO-level testing capabilities.

Our advantages include:

Experienced composite materials scientists and engineers

Advanced testing and analytical instrumentation

CRO-level confidentiality and data integrity

Customized evaluation programs

Clear, engineering-focused reporting

Alignment with global composite testing standards

We work collaboratively with clients to ensure evaluation results directly support design optimization, risk reduction, and successful commercialization.