Creep & Stress Rupture Testing Services

Materials exposed to constant mechanical stress at elevated temperatures can slowly deform or eventually fail over time, even when operating below their immediate strength limits. This time-dependent behavior, known as creep, is a critical consideration for components used in high-temperature and long-duration applications. At Genuine Testing, we provide advanced creep and stress rupture testing services to evaluate long-term material performance under sustained load. As a trusted Contract Research Organization (CRO), we support manufacturers, engineers, and researchers by delivering reliable data on material deformation, stability, and time-to-failure. Our creep and stress rupture testing services help organizations make informed decisions related to material selection, design safety margins, and service life prediction.

Understanding Creep & Stress Rupture Behavior

Creep is the gradual, permanent deformation of a material when subjected to a constant load over an extended period, typically at elevated temperatures. Stress rupture testing, on the other hand, measures the time it takes for a material to fail under a constant applied stress.

Creep behavior is commonly divided into three stages:

Primary creep, where deformation rate decreases over time

Secondary creep, characterized by a steady deformation rate

Tertiary creep, where deformation accelerates leading to failure

Stress rupture testing provides critical insight into:

Long-term strength under sustained load

Time-to-failure characteristics

Safe operating limits for materials

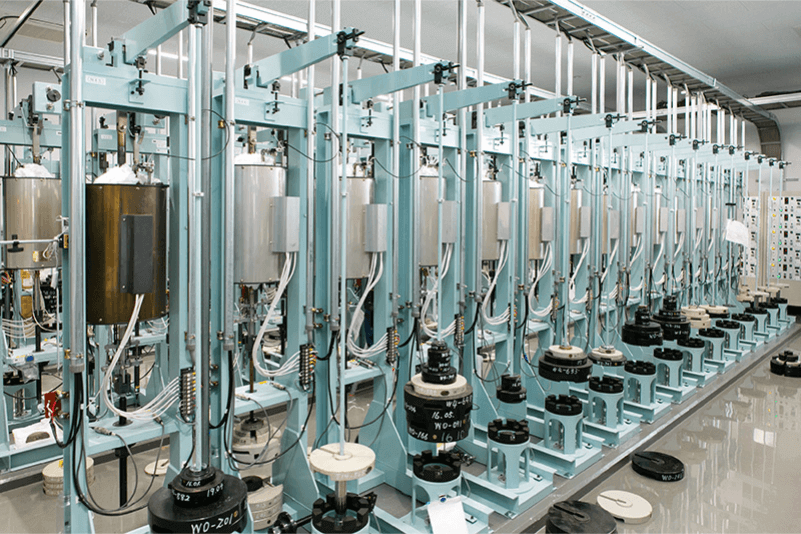

Our Creep & Stress Rupture Testing Capabilities

Genuine Testing offers comprehensive creep and stress rupture testing services using advanced equipment designed for long-duration and high-temperature testing. Our laboratory is capable of maintaining precise load and temperature control to ensure accurate and repeatable results.

Our capabilities include:

Constant load creep testing

Stress rupture and time-to-failure testing

High-temperature testing environments

Long-term deformation measurement

Customized test protocols based on service conditions

Long-Term Deformation & Failure Analysis

Understanding deformation trends and failure mechanisms is essential for predicting material behavior over extended service periods. At Genuine Testing, we provide detailed analysis alongside creep and stress rupture testing to help clients interpret results effectively.

Our analysis includes:

Measurement of creep strain versus time

Identification of deformation rates

Evaluation of failure modes

Comparison of material performance under identical conditions

Correlation of laboratory data with real-world service environments

Industries We Support

Creep and stress rupture testing is critical for industries that rely on materials operating under sustained stress and elevated temperatures. We support clients across a wide range of sectors, including:

Energy & Power Generation – boilers, turbines, and heat exchangers

Aerospace & Aviation – high-temperature alloys and engine components

Oil & Gas & Petrochemical – piping, pressure vessels, and reactors

Industrial Processing – furnaces and thermal equipment

Automotive & Transportation – exhaust systems and engine components

Each application presents unique challenges, and our testing programs are tailored to reflect actual operating conditions.

Why Creep & Stress Rupture Testing Is Critical

Failure due to creep or stress rupture often occurs after long periods of operation, making it difficult to detect without proper testing. Creep and stress rupture testing helps organizations:

Predict long-term service life

Establish safe operating conditions

Improve design safety margins

Reduce risk of catastrophic failures

Support regulatory compliance and certification

Incorporating long-term performance testing early in development significantly improves reliability and safety.

Why Choose Genuine Testing

Clients trust Genuine Testing for creep and stress rupture testing because of our technical expertise, rigorous methodologies, and commitment to quality.

Our advantages include:

Experienced materials scientists and engineers

Advanced high-temperature testing equipment

CRO-level confidentiality and data integrity

Customized testing programs

Clear, detailed technical reporting

Compliance with global creep testing standards

We work collaboratively with clients to ensure test data directly supports engineering decisions and long-term performance goals.