Elastomer & Rubber Testing Services

Elastomers and rubber materials are essential components in products that require flexibility, resilience, sealing performance, and vibration damping. Their unique elastic behavior makes them highly effective across a wide range of industries, but also sensitive to factors such as temperature, environmental exposure, and long-term aging. At Genuine Testing, we provide comprehensive elastomer and rubber testing services to evaluate material performance, durability, and reliability under real-world operating conditions. As a trusted Contract Research Organization (CRO), we support manufacturers, engineers, and product developers with accurate data on elastomer behavior and performance. Our elastomer and rubber testing services help ensure that materials meet functional requirements, regulatory standards, and long-term reliability expectations.

Understanding Elastomer & Rubber Material Behavior

Elastomers differ significantly from rigid materials due to their ability to undergo large elastic deformation and recover their original shape. This behavior is influenced by formulation, crosslink density, fillers, and environmental conditions.

Key characteristics evaluated during elastomer and rubber testing include:

Elasticity and tensile strength

Compression set and resilience

Tear and abrasion resistance

Environmental and thermal stability

Aging and degradation behavior

Our Elastomer & Rubber Testing Capabilities

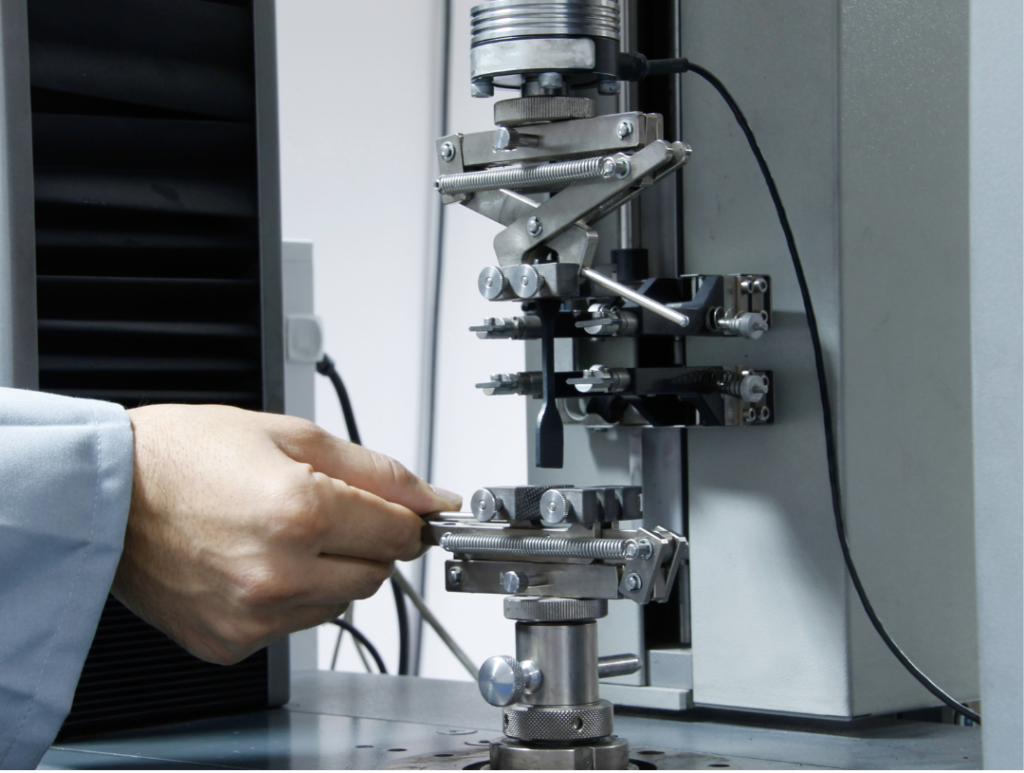

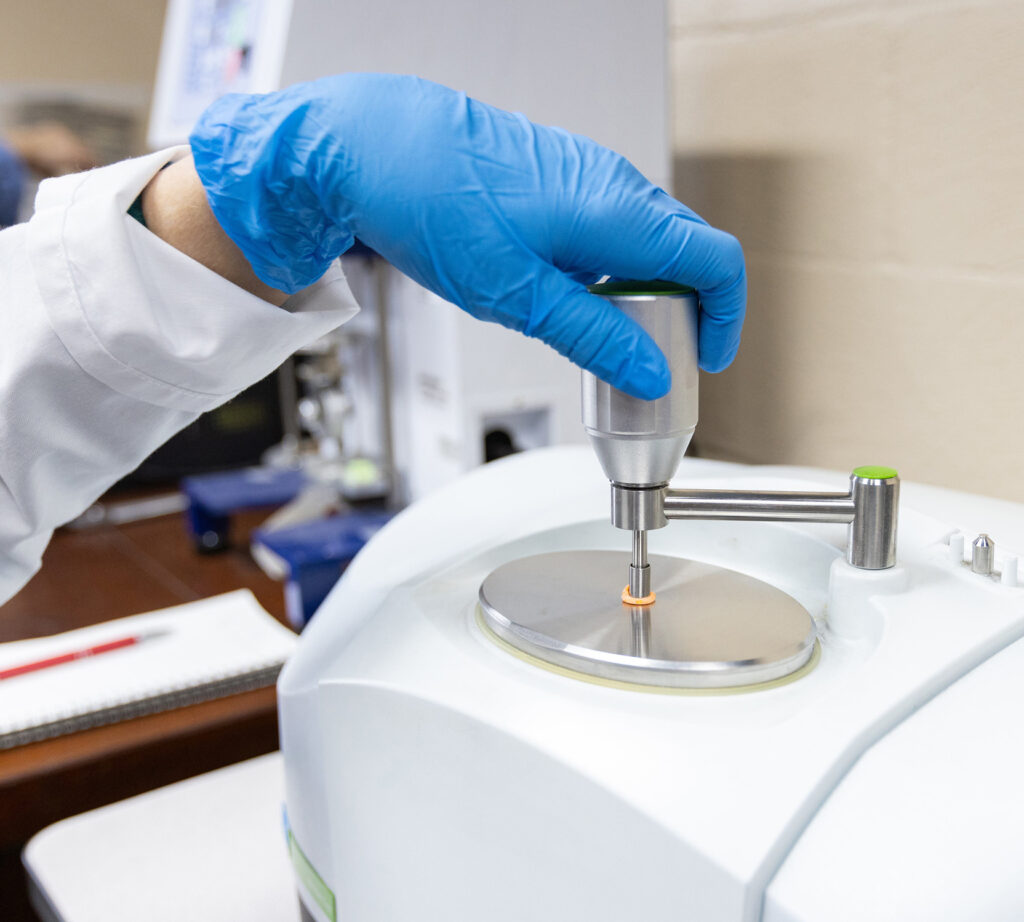

Genuine Testing offers a broad range of elastomer and rubber testing services designed to evaluate material behavior under mechanical, thermal, and environmental conditions. Our laboratory is equipped with specialized instrumentation to test natural and synthetic elastomers.

Our testing capabilities include:

Tensile, elongation, and tear testing

Compression set and resilience evaluation

Hardness and flexibility assessment

Environmental exposure and aging studies

Comparative testing of elastomer formulations

Mechanical, Environmental & Aging Evaluation

Elastomers are often exposed to repeated loading, environmental exposure, and long-term aging, which can significantly affect performance. At Genuine Testing, we evaluate how these factors impact elastomer properties and functionality.

Our evaluation approach includes:

Assessment of mechanical behavior under cyclic and static loads

Evaluation of environmental exposure effects such as heat and humidity

Analysis of aging-related changes in elasticity and strength

Comparison of new and aged material performance

Identification of degradation and failure mechanisms

Industries We Support

Elastomer and rubber testing is critical across industries where sealing, flexibility, and vibration control are essential. We support clients in a wide range of sectors, including:

Automotive & Transportation – seals, gaskets, hoses, and mounts

Medical Devices & Healthcare – elastomer components requiring consistency and safety

Industrial Equipment – vibration isolators and flexible components

Energy & Power Generation – elastomers exposed to harsh environments

Consumer Products – flexible and impact-absorbing components

Aerospace & Defense – high-performance elastomer applications

Why Choose Genuine Testing

Clients choose Genuine Testing for elastomer and rubber testing because of our technical expertise, scientific rigor, and CRO-level service standards.

Our advantages include:

Experienced polymer and elastomer specialists

Advanced elastomer testing instrumentation

CRO-level confidentiality and data integrity

Customized testing programs tailored to application needs

Clear, actionable technical reporting

Compliance with global elastomer testing standards