Environmental Stress Testing Services

Materials and components are frequently exposed to harsh environmental conditions that can significantly impact performance, reliability, and service life. Temperature extremes, humidity, thermal cycling, and prolonged environmental exposure can accelerate degradation and lead to premature failure if not properly evaluated. At Genuine Testing, we provide comprehensive environmental stress testing services to assess how materials perform under realistic and accelerated environmental conditions. As a trusted Contract Research Organization (CRO), we help manufacturers, engineers, and researchers identify potential vulnerabilities, validate durability, and ensure long-term reliability. Our environmental stress testing services support product development, quality assurance, and regulatory compliance across a wide range of industries.

Understanding Environmental Stress Effects on Materials

Environmental stress testing evaluates how external factors such as temperature, humidity, and environmental exposure influence material behavior over time. These factors can affect mechanical properties, chemical stability, dimensional integrity, and overall performance.

Common environmental stress factors include:

Temperature extremes and thermal cycling

High humidity and moisture exposure

Prolonged environmental aging

Combined environmental and mechanical stress

Repeated exposure and recovery cycles

Our Environmental Stress Testing Capabilities

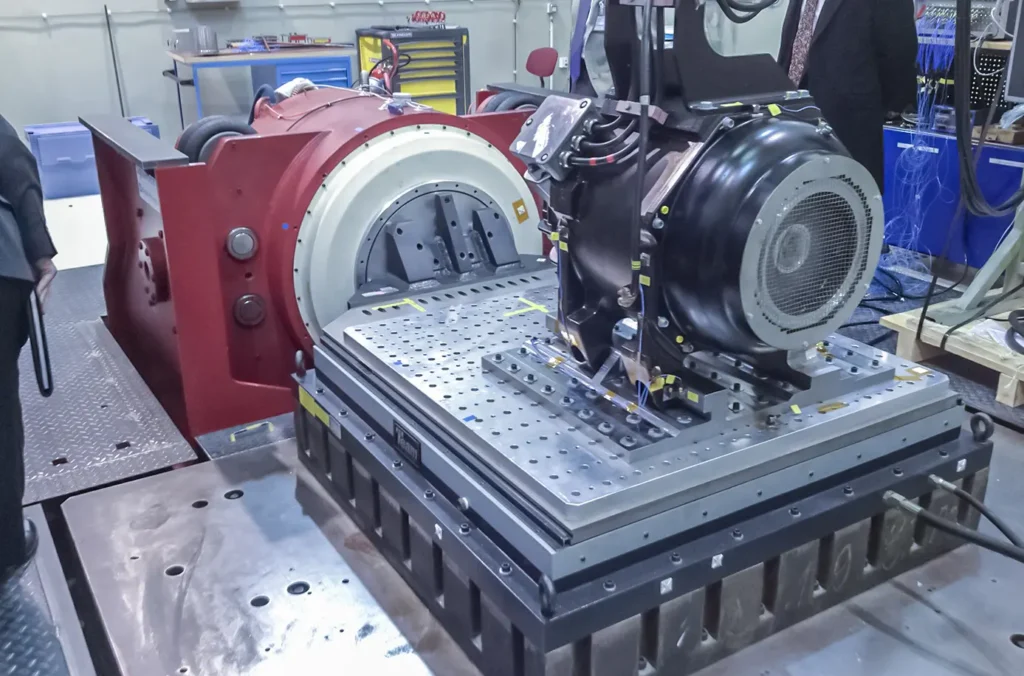

Genuine Testing offers a wide range of environmental stress testing services designed to replicate real-world operating conditions and accelerate aging processes. Our laboratory is equipped with advanced environmental chambers and monitoring systems to ensure precise control and repeatability.

Our testing capabilities include:

Temperature and humidity exposure testing

Thermal cycling and thermal shock evaluation

Accelerated aging studies

Environmental conditioning prior to mechanical testing

Customized exposure protocols based on service conditions

Accelerated Aging & Reliability Evaluation

Accelerated aging is a critical component of environmental stress testing, allowing materials to be evaluated for long-term performance within shorter timeframes. At Genuine Testing, we design accelerated aging protocols that simulate years of environmental exposure.

Our reliability evaluation includes:

Monitoring of property changes over exposure time

Identification of degradation mechanisms

Comparison of aged and unaged material performance

Correlation of laboratory results with expected service life

Assessment of material suitability for intended applications

Industries We Support

Environmental stress testing is essential across industries where materials are exposed to variable or extreme environments. We support clients in a wide range of sectors, including:

Aerospace & Defense – materials exposed to temperature extremes and cycling

Automotive & Transportation – components subject to environmental exposure

Energy & Power Generation – materials operating in harsh outdoor environments

Medical Devices – durability and reliability under controlled conditions

Construction & Infrastructure – materials exposed to weather and environmental aging

Industrial Manufacturing – quality assurance and reliability validation

Why Choose Genuine Testing

Clients choose Genuine Testing for environmental stress testing because of our technical expertise, rigorous methodologies, and client-focused approach.

Our advantages include:

Experienced materials scientists and engineers

Advanced environmental testing equipment

CRO-level confidentiality and data integrity

Customized testing programs

Clear, actionable technical reporting

Compliance with global environmental testing standards