Tribology & Friction Testing Services

Tribology and friction play a critical role in the performance, efficiency, and durability of materials and mechanical systems. Whenever surfaces come into contact and move relative to one another, friction and wear influence energy loss, heat generation, and material degradation. At Genuine Testing, we provide advanced tribology and friction testing services to evaluate surface interactions and optimize material performance in real-world applications. As a trusted Contract Research Organization (CRO), we support manufacturers, engineers, and researchers by delivering accurate data on friction behavior, wear mechanisms, and surface performance. Our tribology testing services help clients reduce wear-related failures, improve efficiency, and extend component service life.

Understanding Tribology & Friction

Tribology is the scientific study of friction, wear, and lubrication between interacting surfaces in relative motion. Friction testing focuses on measuring the resistance to motion between surfaces, often expressed as the coefficient of friction. Together, these factors determine how materials perform under sliding, rolling, or oscillating contact.

Key tribological factors evaluated through testing include:

Coefficient of friction under varying loads and speeds

Surface wear rates and damage mechanisms

Lubrication effectiveness and compatibility

Contact pressure and surface roughness effects

Temperature and environmental influences on friction behavior

Our Tribology & Friction Testing Capabilities

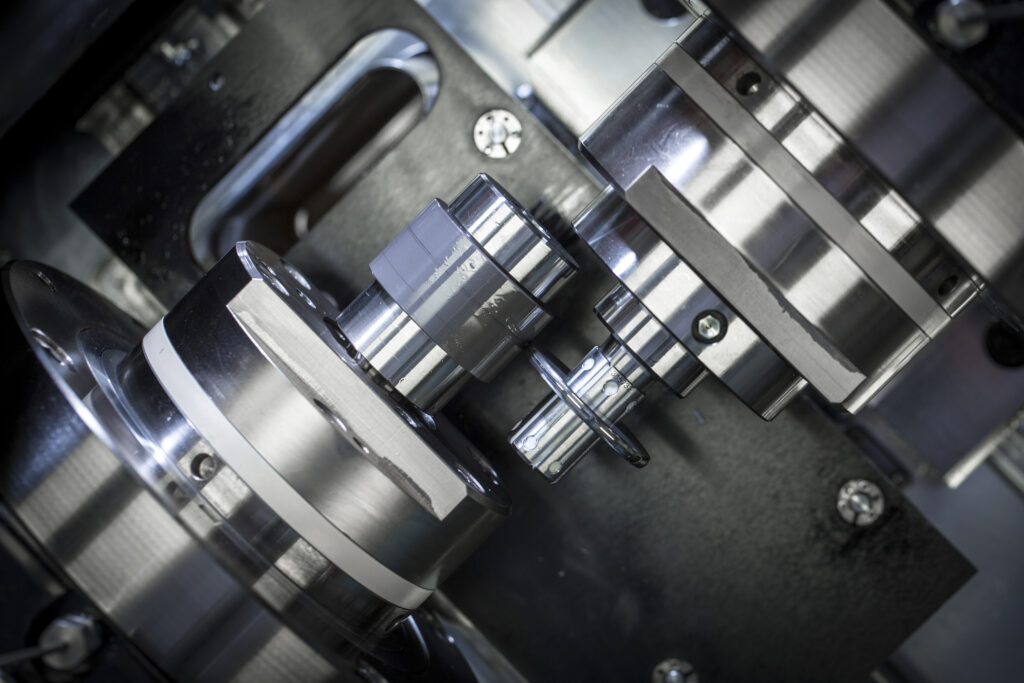

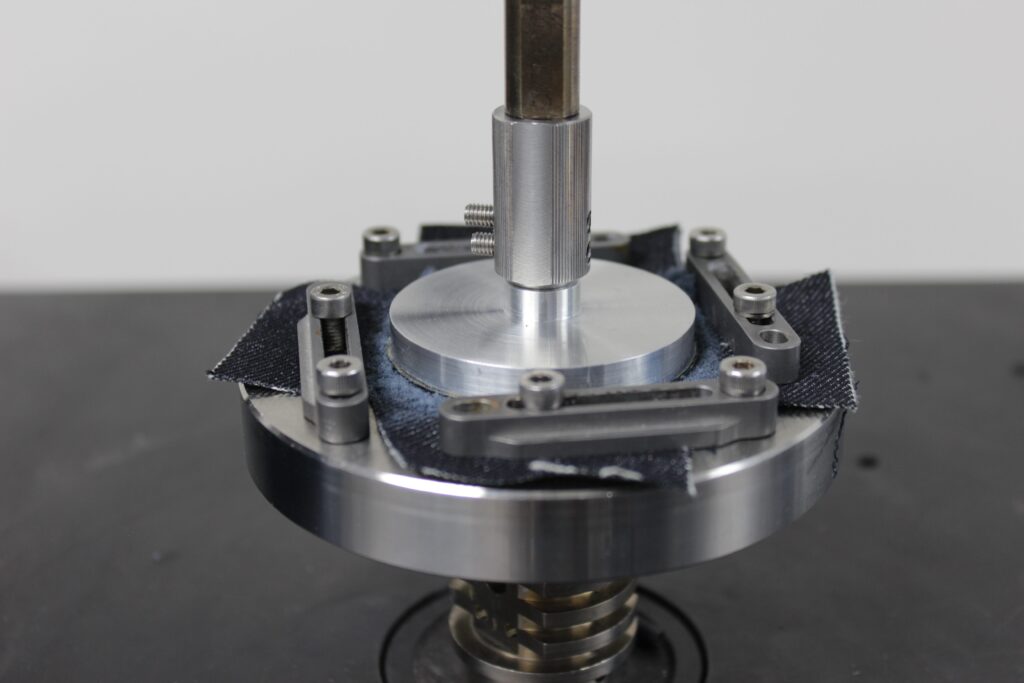

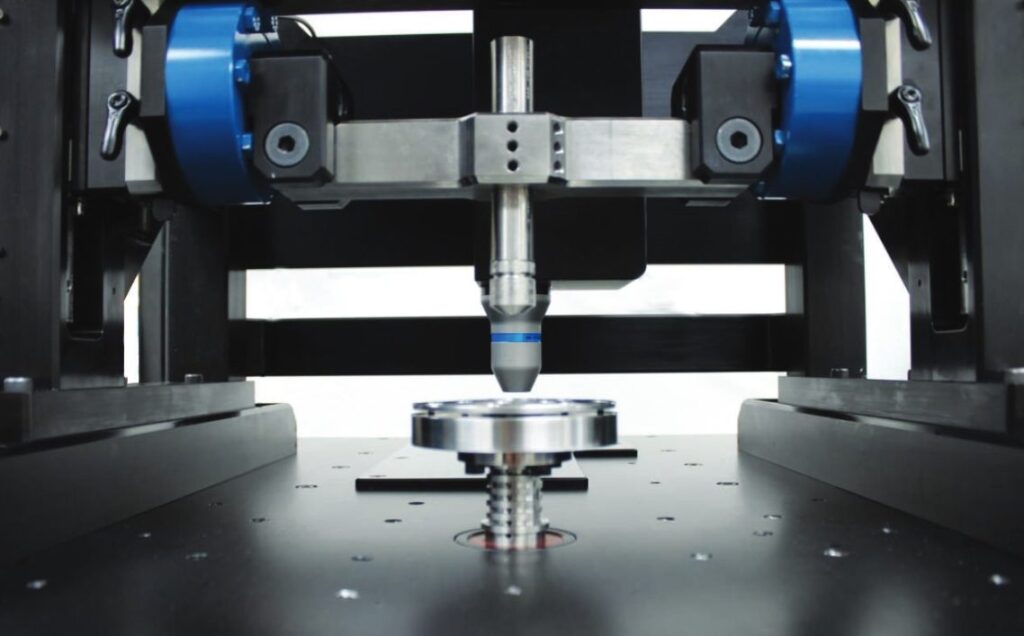

Genuine Testing offers comprehensive tribology and friction testing services using advanced instrumentation and controlled testing environments. Our laboratory can simulate real operating conditions and measure surface interactions with high precision.

Our tribology and friction testing capabilities include:

Coefficient of friction measurement

Sliding, rolling, and reciprocating wear testing

Evaluation of dry and lubricated contact conditions

Comparative testing of materials, coatings, and surface treatments

Pre- and post-test surface characterization

Surface Interaction & Performance Analysis

Understanding how surfaces interact during operation is critical for improving durability and efficiency. At Genuine Testing, we combine tribology testing with detailed analysis to identify wear mechanisms and performance limitations.

Our analysis includes:

Measurement of friction behavior over time

Identification of wear patterns and surface damage

Evaluation of lubrication performance and breakdown

Comparison of alternative material or coating options

Correlation of laboratory results with real-world performance

Industries We Support

Tribology and friction testing is essential for industries where moving parts, surface contact, and wear are critical factors. We support clients across a wide range of sectors, including:

Automotive & Transportation – bearings, gears, and braking systems

Industrial Machinery – sliding and rotating components

Energy & Power Generation – turbines and mechanical systems

Aerospace & Defense – moving assemblies and high-performance materials

Medical Devices – implants and mechanical medical components

Manufacturing & Tooling – surface-treated and coated components

Why Choose Genuine Testing

Clients choose Genuine Testing for tribology and friction testing because of our technical expertise, rigorous methodologies, and collaborative approach.

Our advantages include:

Experienced tribology and materials specialists

Advanced friction and wear testing instrumentation

CRO-level confidentiality and data integrity

Customized testing programs aligned with service conditions

Clear, actionable technical reporting

Compliance with global tribology testing standards