Wear & Abrasion Testing Services

Wear and abrasion are among the most common causes of material degradation, performance loss, and premature product failure. Components that experience repeated contact, friction, or surface loading can gradually deteriorate, even when overall structural strength appears adequate. At Genuine Testing, we provide advanced wear and abrasion testing services to evaluate how materials perform under real-world mechanical interaction. As a trusted Contract Research Organization (CRO), we help manufacturers, engineers, and product developers understand surface durability, compare material options, and improve long-term reliability. Our wear and abrasion testing solutions support product development, quality assurance, failure prevention, and regulatory compliance across a wide range of industries.

Importance of Wear & Abrasion Testing

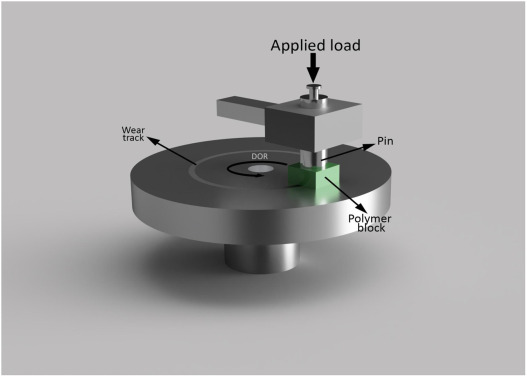

Wear testing evaluates how materials lose mass, thickness, or functionality due to repeated mechanical interaction. Abrasion testing specifically focuses on resistance to scraping, rubbing, or erosive contact caused by hard particles or rough surfaces.

Understanding wear behavior is critical because surface degradation often leads to:

Reduced efficiency and performance

Increased friction and heat generation

Component misalignment or failure

Higher maintenance and replacement costs

Wear and abrasion testing provides valuable insight into how materials behave under sliding, rolling, or abrasive conditions, enabling informed decisions during material selection and design.

Our Wear & Abrasion Testing Capabilities

Genuine Testing offers comprehensive wear and abrasion testing services using standardized and application-specific methodologies. Our laboratory is equipped to simulate real operating conditions and measure material response with high precision.

Key wear and abrasion testing capabilities include:

Sliding and rolling wear testing

Abrasive wear resistance evaluation

Surface friction coefficient measurement

Comparative material performance testing

Pre- and post-test surface characterization

Surface Degradation Analysis & Reporting

Understanding how and why wear occurs is just as important as measuring it. At Genuine Testing, we combine wear testing with detailed surface analysis to identify wear mechanisms and failure modes.

Our reporting typically includes:

Quantitative wear rate measurements

Surface damage observations

Friction behavior trends

Material comparison summaries

Clear conclusions and improvement recommendations

By linking test results to real-world performance, we help clients optimize material selection, surface treatments, and design features that reduce wear-related risks.

Industries We Support

Our wear and abrasion testing services are trusted by organizations across multiple industries, including:

Automotive & Transportation – moving parts, bearings, and interior materials

Industrial Machinery – components exposed to continuous friction

Construction & Infrastructure – materials subject to abrasion and erosion

Energy & Power Generation – rotating and high-contact components

Polymers & Elastomers – wear-resistant plastics and rubber materials

Coatings & Surface Treatments – durability and performance validation

Each industry presents unique wear challenges, and our customized testing programs are designed to address specific operational conditions.

Why Wear Testing Is Essential for Product Reliability

Wear-related failures often develop gradually and may go unnoticed until performance is significantly compromised. Wear and abrasion testing helps organizations:

Predict material lifespan and service intervals

Improve durability and reliability

Reduce downtime and maintenance costs

Prevent unexpected failures

Validate design changes and surface treatments

Incorporating wear testing early in the development process allows teams to identify risks before products are released into the market.

Why Choose Genuine Testing

Genuine Testing is a trusted partner for wear and abrasion testing because of our technical expertise and client-focused approach.

Our strengths include:

Experienced materials scientists and engineers

Advanced wear testing instrumentation

CRO-level confidentiality and data integrity

Customized test methods tailored to application needs

Fast turnaround times with dependable results

Compliance with global testing standards

We collaborate closely with clients to ensure test results translate into meaningful improvements in product performance.