Next-Generation Materials Intelligence: How Genuine Testing Is Redefining Plastics Performance, Elastomer Testing, and Composition Materials Identification

In today’s fast-moving industrial landscape, materials are no longer judged solely by their basic properties. Performance, durability, compliance, sustainability, and innovation now define success across industries such as automotive, aerospace, construction, energy, healthcare, and advanced manufacturing. As materials become more complex and applications more demanding, the need for precise, technology-driven testing has never been greater.

Genuine Testing, a trusted Contract Research Organization (CRO), stands at the forefront of this evolution. Through cutting-edge Plastics Performance Testing, comprehensive Elastomer Testing Services, and advanced Composition Materials ID, Genuine Testing empowers industries with data-driven insights that transform raw materials into reliable, market-ready solutions. By combining decades of scientific expertise with the latest laboratory technologies, Genuine Testing helps organizations innovate confidently while meeting stringent global standards.

The Changing Landscape of Materials Testing

Modern product development demands faster time-to-market, higher performance benchmarks, and strict regulatory compliance. At the same time, sustainability initiatives and material innovation are reshaping how plastics, elastomers, and composite materials are designed and evaluated.

Traditional testing methods alone are no longer sufficient. Industries now rely on advanced analytical tools, high-resolution imaging, and predictive performance modeling to understand how materials behave under real-world conditions. Genuine Testing addresses these challenges by integrating next-generation technologies into every stage of material analysis, ensuring accuracy, transparency, and actionable results.

Advanced Plastics Performance Testing: Engineering Reliability for the Future

Plastics remain one of the most versatile material groups, used across countless applications—from lightweight automotive components to medical devices and high-performance industrial parts. However, modern plastics must withstand extreme mechanical, thermal, chemical, and environmental stresses.

Latest Trends in Plastics Performance Testing

At Genuine Testing, Plastics Performance Testing has evolved to reflect the latest industry trends:

Accelerated Aging & Environmental Simulation

Advanced testing protocols now simulate years of exposure to heat, UV radiation, moisture, and chemicals within compressed timeframes. This enables manufacturers to predict long-term performance and failure modes with greater confidence.High-Precision Mechanical Testing

Modern tensile, impact, fatigue, and creep testing methods provide detailed insights into how plastics perform under real operational loads. These tests help optimize material selection and product design.Thermal and Rheological Analysis

State-of-the-art thermal analysis techniques allow engineers to evaluate melting behavior, glass transition temperatures, and thermal stability, ensuring plastics perform consistently under temperature fluctuations.Sustainability-Focused Testing

As recycled and bio-based plastics gain popularity, performance testing now plays a critical role in validating strength, durability, and consistency compared to traditional materials.

Genuine Testing’s advanced laboratory infrastructure ensures that every plastics performance test delivers reproducible, industry-compliant results that support product reliability and regulatory approval.

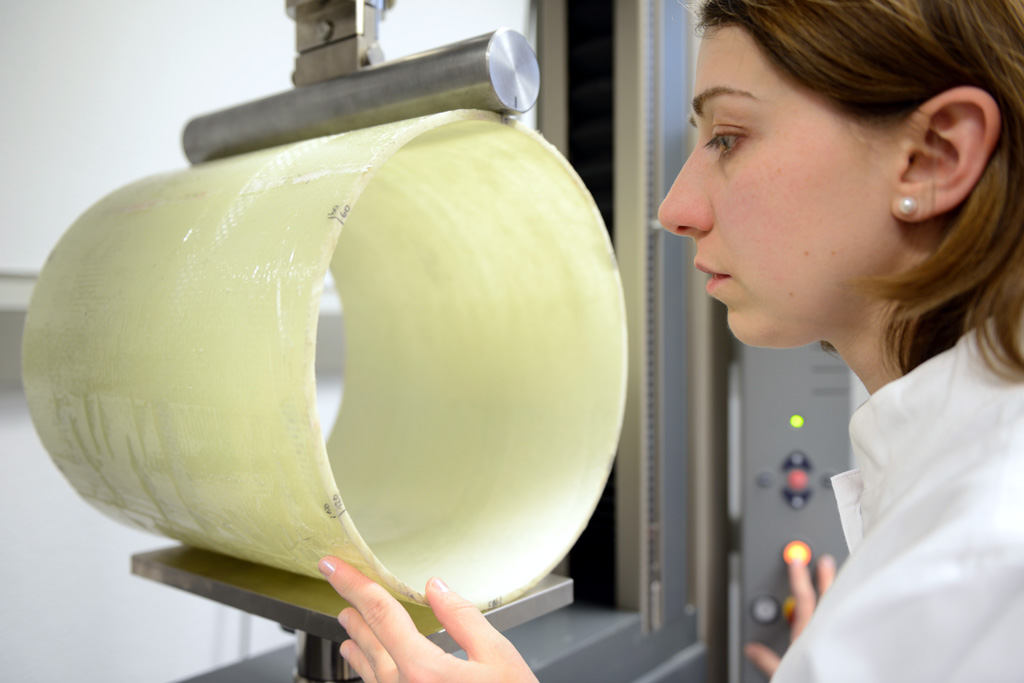

Elastomer Testing Services: Precision for Flexible and Resilient Materials

Elastomers are essential in applications where flexibility, elasticity, and resilience are critical. From seals and gaskets to medical components and vibration-damping systems, elastomers must perform flawlessly under repeated stress and varying environments.

Innovations Shaping Elastomer Testing Services

Elastomer Testing Services at Genuine Testing incorporate the latest scientific advancements to address modern performance demands:

Dynamic Mechanical Analysis (DMA)

Advanced DMA techniques evaluate viscoelastic behavior across a wide temperature and frequency range, offering insights into stiffness, damping, and long-term durability.Chemical Resistance and Compatibility Testing

With elastomers increasingly exposed to fuels, oils, solvents, and aggressive chemicals, modern testing focuses on predicting material degradation and swelling behavior.Fatigue and Wear Analysis

Enhanced fatigue testing methods simulate repeated loading cycles, helping manufacturers design elastomer components that last longer and perform more reliably.Performance Validation for Specialized Applications

Industries such as healthcare and aerospace require elastomers that meet exacting standards. Genuine Testing ensures compliance with international regulations while maintaining material integrity.

By combining advanced instrumentation with deep material science expertise, Genuine Testing delivers Elastomer testing services that reduce risk, enhance product performance, and support innovation.

Composition Materials ID: Unlocking Material Intelligence

Understanding what a material is made of is just as important as knowing how it performs. Composition Materials ID has become a cornerstone of quality assurance, failure analysis, and competitive benchmarking.

Cutting-Edge Technologies in Materials Identification

Genuine Testing employs advanced analytical techniques to deliver precise and reliable material identification:

High-Resolution Microscopy

Advanced microscopy reveals microstructural details that impact performance, durability, and failure mechanisms.Chemical and Spectroscopic Analysis

Modern analytical methods allow for accurate identification of polymers, fillers, additives, and contaminants, even at trace levels.Contaminant Identification and Root Cause Analysis

Composition Materials ID plays a crucial role in identifying unexpected impurities that may compromise product quality or safety.Reverse Engineering and Competitive Analysis

Manufacturers increasingly rely on material composition analysis to benchmark products, validate suppliers, and ensure consistency across production batches.

At Genuine Testing, composition analysis goes beyond identification. The focus is on delivering meaningful insights that guide material selection, product improvement, and regulatory compliance.

Integration of Digital Technologies in Materials Testing

One of the most significant trends shaping the future of materials testing is digital transformation. Genuine Testing integrates advanced data analysis, automation, and digital reporting to enhance accuracy and efficiency.

Data-Driven Insights

Sophisticated data interpretation tools transform complex datasets into clear, actionable conclusions.Enhanced Traceability and Transparency

Digital workflows ensure every test result is traceable, reproducible, and aligned with international quality standards.Faster Decision-Making

By streamlining laboratory processes, Genuine Testing helps clients accelerate R&D timelines without compromising accuracy.

This technology-driven approach allows clients to move from sample to solution with confidence and clarity.

Why Industries Trust Genuine Testing

Choosing the right partner for plastics performance testing, elastomer testing services, and composition materials ID can define the success of a product or project. Genuine Testing stands out through its unwavering commitment to quality, innovation, and client collaboration.

Decades of Proven Expertise

As an experienced CRO, Genuine Testing brings deep scientific knowledge across diverse material systems.Comprehensive, Integrated Services

From advanced microscopy to environmental and chemical analysis, all services are delivered under one roof.Cutting-Edge Laboratory Infrastructure

The laboratory is equipped with the latest instruments, ensuring accuracy, reliability, and compliance with global standards.Client-Focused Collaboration

Every project is approached with a tailored methodology designed to meet specific technical and regulatory needs.Confidentiality and Compliance

Genuine Testing upholds the highest standards of data security, discretion, and regulatory adherence.

Supporting Innovation Across Industries

From concept development to commercialization, Genuine Testing supports organizations at every stage of the product lifecycle. Whether validating new plastic formulations, optimizing elastomer performance, or identifying complex material compositions, the company delivers solutions that drive real-world impact.

Industries benefit from reduced risk, improved product performance, and faster time-to-market—all powered by accurate, science-driven insights.

The Future of Materials Testing with Genuine Testing

As materials science continues to evolve, so do the expectations placed on testing laboratories. Sustainability, advanced composites, battery materials, and next-generation polymers will require even more precise and innovative testing approaches.

Genuine Testing remains committed to staying ahead of these trends by continuously investing in technology, expertise, and research methodologies. Through advanced Plastics Performance Testing, robust Elastomer Testing Services, and precise Composition Materials ID, Genuine Testing is not just analyzing materials—it is shaping the future of material innovation.