Engineering the Future of Materials: Advanced Testing, Innovation, and Reliability Across Plastics, Polymers, Ceramics, and Glass

Material science has entered a new era where innovation is shaped by data, advanced instrumentation, and cross-disciplinary research. Manufacturers across aerospace, automotive, construction, energy, electronics, and healthcare now require deeper insights into material behavior at micro and nano levels. Traditional testing methods alone are no longer sufficient.

Genuine Testing addresses this challenge by integrating advanced analytical techniques with decades of experience in contract research. The result is a comprehensive testing ecosystem that not only evaluates material properties but also uncovers performance insights that drive smarter design, improved durability, and regulatory compliance.

Plastics and Polymers: Pushing Performance Beyond Limits

The Evolution of Polymer Science

Plastics and polymers are at the heart of modern innovation, from lightweight automotive components to medical-grade devices and sustainable packaging. Recent trends in polymer science focus on:

-

High-performance engineering plastics

-

Bio-based and recyclable polymers

-

Enhanced thermal, chemical, and mechanical resistance

-

Smart polymers with adaptive properties

As materials become more complex, precise testing becomes essential.

Advanced Testing Technologies for Polymers

At Genuine Testing, Plastics and polymers undergo rigorous evaluation using cutting-edge techniques such as:

-

Thermal analysis to assess heat resistance and stability

-

Mechanical testing for strength, flexibility, and fatigue behavior

-

Chemical composition analysis to ensure purity and compliance

-

Microscopy and surface analysis to detect defects and microstructural variations

These insights help manufacturers optimize formulations, improve product lifespan, and ensure materials perform reliably under real-world conditions.

Adhesives and Rubbers: Engineering Stronger Bonds and Greater Flexibility

Rising Demand for High-Performance Adhesives

Adhesives and rubbers play a critical role in lightweight construction, electronics, automotive assemblies, and medical applications. Modern industries demand materials that offer:

-

Superior bonding strength

-

Resistance to temperature, chemicals, and environmental stress

-

Long-term durability and elasticity

Innovations in Adhesive and Rubber Testing

Genuine Testing applies advanced methodologies to evaluate:

-

Adhesion strength and peel resistance

-

Elasticity, compression, and recovery behavior

-

Aging and environmental degradation

-

Failure analysis under dynamic stress

By simulating real-world conditions, Genuine Testing ensures Adhesives and rubbers meet both performance and safety expectations, helping clients reduce failures and enhance product reliability.

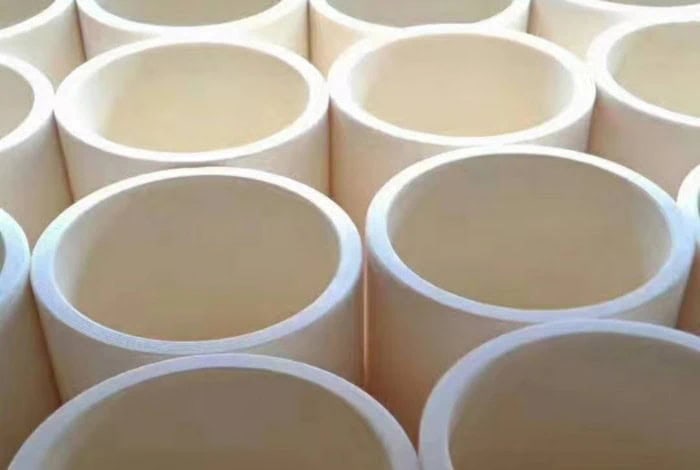

Ceramics: Precision Testing for High-Performance Applications

The Growing Role of Advanced Ceramics

Ceramics are no longer limited to traditional uses. Today, advanced ceramics are critical in electronics, aerospace, energy systems, medical implants, and industrial manufacturing. Their unique properties include:

-

Extreme temperature resistance

-

High hardness and wear resistance

-

Electrical insulation and chemical stability

State-of-the-Art Ceramic Analysis

Testing ceramics requires specialized expertise and equipment. Genuine Testing offers:

-

Microstructural analysis to evaluate grain size and porosity

-

Mechanical strength testing under extreme conditions

-

Thermal shock and heat resistance analysis

-

Failure and fracture analysis

These advanced capabilities allow manufacturers to validate ceramic performance, improve formulations, and ensure consistency across production batches.

Refractories and Glass: Strength Under Extreme Conditions

Materials Built for Harsh Environments

Refractories and glass materials are essential in industries such as steel, cement, energy, and construction. They must withstand:

-

High temperatures

-

Thermal cycling

-

Mechanical stress

-

Chemical corrosion

Advanced Testing for Reliability and Safety

Genuine Testing delivers comprehensive analysis for refractories and glass through:

-

Thermal conductivity and expansion testing

-

Chemical resistance evaluation

-

Structural integrity and durability assessments

-

Contaminant identification and purity analysis

By identifying weaknesses before deployment, clients can prevent costly failures, extend service life, and maintain operational efficiency.

Microscopy and High-Resolution Material Insights

Seeing Beyond the Surface

Modern material innovation depends on understanding structures at microscopic and sub-microscopic levels. Genuine Testing leverages advanced microscopy techniques to reveal:

-

Micro-cracks, voids, and defects

-

Phase distribution and material homogeneity

-

Surface interactions and bonding quality

High-resolution imaging provides actionable insights that directly influence material design, quality control, and failure prevention strategies.

Battery Materials and Emerging Technologies

As industries transition toward electrification and renewable energy, battery materials have become a focal point of innovation. Genuine Testing supports this shift with:

-

Performance and degradation analysis of battery components

-

Contaminant detection that impacts efficiency and safety

-

Environmental and lifecycle assessments

These services enable manufacturers to improve energy storage solutions while meeting safety and sustainability standards.

The Genuine Testing Advantage: A Trusted Contract Research Organization

A Collaborative, Client-Centered Approach

What sets Genuine Testing apart is its commitment to partnership. Every project begins with a deep understanding of the client’s goals, challenges, and regulatory requirements. The team works collaboratively to design customized testing strategies that deliver meaningful results.

From Concept to Commercialization

As a leading CRO, Genuine Testing supports clients across the entire product lifecycle:

-

Early-stage research and material selection

-

Method development and validation

-

Regulatory compliance and quality assurance

-

Performance optimization and failure analysis

This end-to-end support accelerates innovation while reducing risk and development time.

Technology, Integrity, and Precision at the Core

Cutting-Edge Infrastructure

Genuine Testing’s laboratories are equipped with the latest analytical instruments, ensuring accuracy, reproducibility, and compliance with international standards.

Data-Driven Decision Making

Beyond generating results, the team focuses on data interpretation and actionable insights, empowering clients to make informed, confident decisions.

Confidentiality and Compliance

Every project is handled with the highest levels of discretion, data security, and regulatory adherence, reinforcing Genuine Testing’s reputation as a trusted partner.

Shaping the Future of Material Science

The future of materials lies in smarter design, sustainable innovation, and uncompromising quality. Whether it’s advanced polymers, high-performance adhesives, resilient Ceramics, Refractories and Glass, the need for reliable testing and research has never been greater.

Genuine Testing continues to lead this evolution by combining scientific curiosity, advanced technology, and proven expertise. Through precision-driven material testing and contract research services, the company empowers industries to push boundaries, ensure safety, and deliver products that stand the test of time